Cannabidiol (CBD) is one of the active chemical compounds found in cannabis and is known for a range of possible health benefits, including supporting healthy inflammation and stress, promoting relaxation, and encouraging healthy sleep cycles.

So it’s no surprise that CBD oil has become a popular wellness remedy. But have you ever wondered what goes into making a high-quality CBD tincture?

How CBD Oil is Made: Extraction Methods

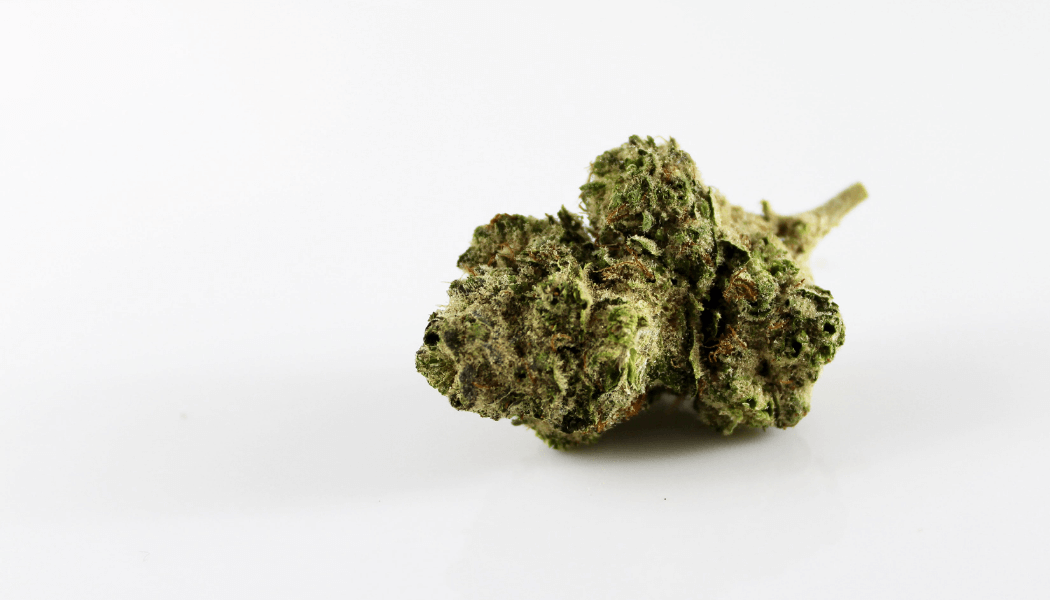

At the beginning of the process, CBD, or cannabidiol, is extracted from the Cannabis sativa plant, specifically from the trichomes — tiny, crystal-like structures found on the flowers, leaves, and stems. These trichomes produce the plant’s resin, which is rich in cannabinoids like CBD and terpenes that contribute to its aroma and flavor.

The process begins with harvesting mature, resin-rich hemp flowers, which are high in CBD and low in THC content. Cannabis plants must contain less than 0.3% THC to be classified as legal hemp in the United States.

Once harvested, the plant material is separated from its essential phytochemical compounds, and various extraction methods are used to isolate the resin. Some newer methods, like freezing the plant immediately after harvest, help preserve natural terpenes and cannabinoids, enhancing effects and ensuring better retention in products like live resin gummies.

CBD extraction methods generally fall into four categories: solvent-based, oil-based, heat-based, and mechanical/physical.

Cooking Oil And Heat

People make CBD oil by extracting it from the cannabis plant. That’s because making a CBD extract can be as simple as taking olive oil, coconut oil, or butter and cooking the finely chopped buds, stems, and leaves of a hemp plant over low to medium heat.

Alternatively, you can preheat the oven and bake the raw green material to decarboxylate (heat-activate) some of the cannabinoids. The heat transforms CBDa, THCa, and CBGa into CBD, THC, and CBG, so that it's much more bioavailable in our system before infusing it with oil.

Cannabinoids (like CBD) and terpenes are fat-soluble, so they bind readily to the oil, and you're able to filter out the plant material, leaving behind many of the beneficial compounds from hemp. This method is the oldest way to create a cannabis extract. However, it's not the best commercial production method, as it's nearly impossible to get consistent extractions.

The Pros:

- Natural, whole hemp CBD oil with very minimal processing

- You can do this at home

The Cons:

- Inconsistent batches

- Difficult to do on a large scale production

Butane Hash Oil (BHO) Extraction

One method of extracting CBD from hemp involves passing butane — a hydrocarbon gas that easily liquefies — through the plant material. Butane, a liquid solvent, dissolves cannabinoids and terpenes from the resinous trichomes of the hemp plant, creating a concentrated extract.

Reputable CBD oil manufacturing companies that choose to use butane as their solvent will be using instrument-grade butane for its purity and low boiling point. Butane extraction is a popular extraction method amongst cannabis hobbyists. This is the extraction method you may be thinking of that results in burnt-down garages and labs.

While modern lab-controlled BHO extraction methods are much safer today, reducing the possibilities of flammable gas leaks with commercial-grade extraction machines and strict government legislation, in 2014 alone, there were a reported 32 BHO explosions in Colorado. Without closed-loop extraction machines, the extremely volatile gas is prone to leak into the environment. Even a small spark can lead to a terribly deadly explosion. Now, back to the lab.

Butane extraction requires post-processing to remove any remaining solvents from the concentrate. This is done in a vacuum oven designed to remove unwanted substances from products by creating a low atmospheric pressure in the oven, allowing chemicals to boil off at lower temperatures without degrading any of the beneficial terpenes or the cannabinoids in the extract.

The Pros:

- It's inexpensive

- It is a fast extraction method

The Cons:

- Bad-post processing can leave butane residue in the final product

- Butane is dangerous to work with

- There are many regulations required to work with butane

- Removes a lot of the beneficial plant waxes, terpenes, and minor cannabinoids

Ethanol Extraction

Another popular method of extracting CBD from hemp is by soaking the plant in ethanol, another liquid solvent. Ethanol is a simple alcohol made from plant fermentation. Like butane, it's also colorless and flammable but has a distinct odor.

Ethanol is a polar solvent because of its chemical makeup, which includes a hydroxyl group (OH) and an ethyl group (C2H5). This allows it to dissolve both water-soluble compounds and fat-soluble cannabinoids like CBD, THC, and CBG found in hemp.

Ethanol extraction is generally considered a safe practice according to the FDA (Food and Drug Administration), and it's a common solvent used in cosmetics, food flavorings, and medical preparations. The hemp material is milled and then added to ethanol to pull and separate the resin-rich trichomes from the organic plant matter. The specific compounds extracted will depend on the temperature of the ethanol and the raw material's condition.

Once the large plant molecules are removed, you have a product that has a consistency that's similar to runny, waxy peanut butter, rich in terpenes, fatty acids, and cannabinoids. This is then filtered, typically via vacuum distillation, to remove the alcohol and smaller unwanted plant molecules, leaving behind the concentrated resin.

The Pros:

- It's more energy-efficient

- Maintains a lot of the natural beneficial compounds in the plant

- It's a generally safe extraction method

The Cons:

- There aren't any cons to the consumer

- It's a time-consuming extraction process

- Requires more steps for a pure hemp extract (without chlorophyll)

Supercritical CO2 Extraction Method

Supercritical CO2 extraction is one of the most efficient ways to extract CBD from hemp. This method is now the gold standard for safe and clean hemp extraction. It’s also better for the environment and safer for workers since it’s non-toxic. This type of CBD processing is the method we use at Neurogan, as it effectively preserves the cannabinoids and allows for the most consistent, potent formulations of CBD oil.

CO2 is a naturally occurring gas — it's what we exhale when we breathe, the by-product of cellular respiration. If this gas escapes into the atmosphere during the extraction process, it won't harm the environment as it's recycled by the plant life in our ecosystem.

Turning CO2 gas into a supercritical state — a substance with properties between a gas and a liquid — involves first cooling the gas and then pressurizing it in special chambers. This requires expensive, highly specialized equipment and a registered facility (state-dependent). CO2 is a gas that reaches a supercritical state at 1071 PSI and 87.98°F (31.1°C) [3].

Hemp is usually crushed or milled before it is placed in these supercritical CO2 machines. The highly pressurized CO2 behaves as a non-volatile solvent to "wash" the plant material, separating the resin-rich trichomes into a thick, viscous, waxy oil. You can get a lot more precise about what compounds you wish to keep in the extracted oil by changing the temperature and pressure settings.

The CO2 extraction method also produces more flavorful and potent whole hemp extracts as it preserves more of the natural compounds found in the hemp plant. At this point, CBD manufacturers may also cold-treat or vacuum distill this product for a more refined CBD extract that's free from chlorophyll, plant waxes, and esters. Those who appreciate the depth and effectiveness of such extraction techniques might enjoy using true full spectrum CBD tinctures available on the market, each exemplifying the high standards set by this method.

The Pros:

- A completely solvent-free final product

- Rich in phytonutrients and has a natural flavor profile

- Non-toxic material, making it safe to work with

The Cons:

- There are no cons to the consumer

- It can be a costly upfront investment for the manufacturer

- It takes longer to extract oil as opposed to solvent methods

Mechanical and Physical Extraction Methods

These types of CBD extraction involve physical force, pressure, or temperature instead of solvents, to separate the CBD from the plant.

Some extraction methods in this category include:

- Ice water extraction: This method involves taking the hemp plant and placing it into a mesh bag before submerging it in ice water. The trichomes freeze off of the plant to be collected and used later.

- Steam distillation: This process involves placing the plant material in a steam chamber, where heat causes essential oils and cannabinoids to evaporate. The steam, carrying these compounds, is then condensed to produce a CBD extract, leaving the plant matter behind.

- Dry ice extraction: Instead of using CO2 in gas form, this method uses solid CO2 — dry ice — to freeze off the trichomes from the other plant matter.

Post-Extraction: How Is CBD Oil Made?

The extraction methods above produce a crude hemp extract, which naturally contains a variety of cannabinoids and terpenes. This crude extract can be used as-is for whole plant CBD oil or further refined to create different types of CBD products.

Once extracted, the CBD oil may undergo additional purification and refinement processes to remove unwanted compounds or isolate specific cannabinoids. The final product can be:

- Full-spectrum CBD – Retains all naturally occurring cannabinoids, terpenes, and flavonoids.

- Broad-spectrum CBD oil – Contains multiple cannabinoids and terpenes but with certain compounds, like THC, removed.

- CBD isolate – Nearly 100% pure CBD, with all other plant compounds removed.

How to Make Whole Plant CBD Oil

Once crude hemp oil is extracted, it can be turned into full-spectrum CBD oil in a fairly straightforward process. The crude extract may be blended with additional extracts to achieve a desired cannabinoid ratio or combined with a carrier oil. The result is a CBD-rich product containing a full range of cannabinoids, terpenes, and flavonoids, typically appearing clear or amber in color.

How to Make CBD Isolate Oil and Broad Spectrum CBD Oil

However, not all cannabinoids are desirable or even legal, depending on the part of the world you’re in. Of course, we're talking about cannabis's notorious psychoactive cannabinoid, THC.

While most CBD oils on the market are made from hemp crops with a low THC content, which won't produce any intoxicating effects, some people may have a sensitivity to the compound and wish to avoid it altogether. In these cases, CBD oil without THC may be your only option to reap the benefits of CBD oil.

There are two types of CBD oil extracts that contain zero traces of THC:

1. Isolate

CBD isolate refers to the pure, unrefined crystalline form of CBD, which is extracted from cannabis. To make CBD isolate, full spectrum CBD extract would undergo further processing to strip away all other cannabinoids, terpenes, and phytonutrients, leaving behind up to 99.9% pure CBD crystals.

There isn't a universal method for making a CBD isolate. The first step is to remove the organic plant matter from the resin using any of the extraction methods we’ve listed, such as ethanol extraction, CO2 extraction, or oil extraction. What’s left is a very crude whole hemp cbd oil extract. This extract then needs to undergo a process called “winterization,” which refines the oil by removing any additional lipids, chlorophyll, and waxes, giving it a consistency that can resemble manuka honey or molasses. A popular winterization method involves soaking the CBD flower extract in alcohol and then freezing it to get rid of any unwanted materials.

The next step in the process is decarboxylating, which we mentioned earlier, to activate the cannabinoids. After that, to purify the extract further, the CBD extract undergoes distillation — a process of selectively heating and cooling substances to remove impurities. Distillation starts by heating a liquid to its unique boiling point to target a compound and transform it into a vapor state. This vapor is then passed through into a separate container, cooled, and condenses, forming a distillate, a key distinction when comparing CBD full-spectrum vs. CBD isolate.

Some CBD manufacturers will run another solvent process after the distillation to get a purity of 99.9% isolate. To convert the extract into a solid form, it will undergo a process called crystallization — producing a fine white crystal powder. This powder will be almost 100% CBD and absent of THC, other cannabinoids, or terpenes. As a powder form is not always convenient for consumers, manufacturers may dissolve the pure CBD isolate powder into a carrier oil for easy consumption.

2. Broad Spectrum Extract

If you still want the benefits of the entourage effect — the effect of terpenes and cannabinoids compounding their benefits to strengthen the effects of CBD — but don't want any THC in the mix, broad spectrum CBD extracts or THC-free CBD are the next best option to full spectrum extracts.

Again, there aren't any formal processes across the industry on how broad spectrum extracts are made. The point of broad spectrum or THC-free CBD oil is to contain a range of cannabinoids and terpenes to aid the overall effectiveness of CBD, minus the THC.

One method to get this extract is to take full spectrum extracts and selectively distill them to remove THC. This will yield a broad spectrum product with a more natural phytochemical profile. This is done by combining a set of isolated compounds — minor cannabinoids, terpenes, flavonoids — with CBD isolate to get a proprietary blend of phytochemicals.

How Hemp & CBD Oil are Made Differently?

Hemp oil that you find in the cooking oil section at your local grocery store is also referred to as "hemp seed oil." Making hemp seed oil is significantly different from creating CBD oil, and its uses are also distinctive.

Hemp oil comes from seeds of hemp crops, whereas CBD can come from non-hemp plants. Since there aren't any cannabinoids in the seeds themselves, it's free from CBD, THC, and any other terpenes you're getting in a CBD oil product.

The hemp seeds are then cold-pressed, which means extracting the natural oils from the seeds without any heat or chemicals. It's a purely mechanical process that involves a high amount of pressure to extract the oil and maintain its integrity and quality.

Hemp seed oil is rich in omega 6 fatty acids, vitamin E, calcium, magnesium, and zinc. It's considered both cooking oil and a health supplement. However, it does not interact with the endocannabinoid system (ECS) because there are no cannabinoids in hemp seed oil.

What Are the Ingredients in CBD Oil?

When you're shopping for a bottle of CBD oil, you'll encounter the amount of CBD contained in the product, typically in mg or sometimes a percentage.

To make CBD oil more user-friendly and palatable, it's combined with a CBD carrier oil. The most popular carrier oils for CBD oils are MCT coconut oil, hemp seed oil, olive oil, or vegetable glycerin. Many brands opt for simple, classic formulas of a CBD extract (full spectrum, broad spectrum, or isolate) combined with a carrier oil. To increase the palatability of these oils, you can find flavored CBD options.

CBD oil is reported to have many benefits to our overall health thanks to its interaction with the ECS, which plays an important role in maintaining homeostasis (balance) in the body by regulating other vital systems.

Testing the Extracted CBD

A lot goes into CBD oil production, which is why it's important to reference a brand's lab testing to ensure their CBD oil is made safely before buying.

While it's not mandatory in the industry, reputable brands send samples of their products to independent labs for a non-biased report of what's in their CBD extract. These reports will include information about the cannabinoid and terpene profile with their respective concentrations. This will be your best indicator of what type of extract the company uses, as there's a general lack of regulation for product labeling.

We've come across bottles that claim to be full spectrum CBD, but have nothing but CBD in the extract. Full spectrum oils tend to cost more, so this was likely a marketing ploy to deceive unsuspecting customers.

How is Cannabidiol (CBD) Oil Made?

CBD oil comes from the resinous trichomes of the bud, stems, and leaves of cannabis plants. CBD oil can either come from hemp or Marijuana, based on the country and manufacturer.

It's then dried and extracted using either supercritical CO2, ethanol, butane, or various other methods to remove the large plant material from the cannabinoids, terpenes, fatty acids, waxes, and other beneficial nutrients found in the resin.

The extracts may then undergo further processing, depending on the desired contents of cannabinoids wanted for the extracts. There isn't one way to create a CBD oil, so we've just outlined the most common CBD extraction methods for making full spectrum, broad spectrum, and isolate extracts.

The first pass in this extraction method is always a full spectrum CBD, but it may go through more processing to isolate certain cannabinoids. These extracts are then combined with a carrier oil for a better user experience and to increase palatability. Depending on the formula, CBD oils can come in different strengths (how much CBD is contained), flavors, and additional ingredients to target its benefits.

Before purchasing any CBD oil product, always reference the independent lab tests that should be accessible on the brand's website. This is the only way to verify what's in the bottle — extract type and strength.

FAQ

How Is CBD Extracted?

CBD oil is made by collecting mature flowering hemp crops high in resin-rich cannabinoids and terpenes and then separating the big organic plant matter from its key phytochemical ingredients. The bulk plant material is then dried and extracted using supercritical CO2, ethanol, or butane to separate the resin's cannabinoids, terpenes, fatty acids, waxes, and other useful elements.

How to Make Pure CBD Oil from Hemp?

There is no standardized process for generating CBD isolate. Ethanol extraction and CO2 are the two most prevalent procedures. After obtaining a very crude whole hemp CBD oil extract, the extract is subjected to a procedure known as “winterization,” which eliminates any remaining lipids, chlorophyll, and waxes.

What Part of the Plant Is CBD Oil Made From?

CBD can be found in both marijuana strains and hemp harvests. However, because hemp is legal and abundantly available in the United States, hemp-derived CBD oils account for the vast majority of CBD oils on the market. Cannabinoids are discovered in the plant's resin-producing trichomes.

Is Third-Party Lab Testing Important?

While not required by law, reputable manufacturers send samples of their products to independent labs for unbiased analysis of what is in their CBD extract. The cannabinoid and terpene profiles, as well as their concentrations, will be included in these reports.